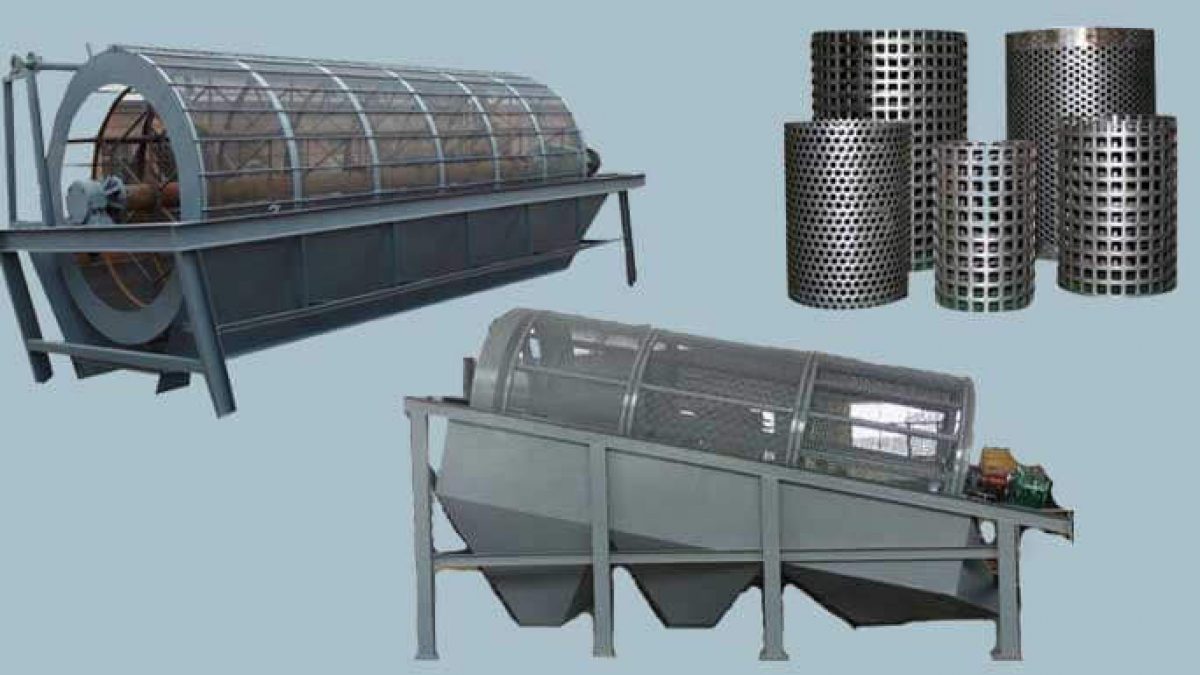

In many different fields, like building, mining, waste management, and recycling, trommel screens are essential tool. These cylindrical drum-shaped screens provide a good way to separate and sort objects based on dimension. The versatility and durability of Trommel Screen are well-known; these qualities are crucial for maximizing material handling operations and reducing running out of operations.

Trommel Screens: Their Functional Value

Trommel screens work by rotating a drum with perforated holes that allow smaller materials to pass through while catching more massive ones. As the drum rotates, the material is constantly sieved and separated into different sizes. This feature makes trommel screens ideal for separating recyclable items, compost, soil, and aggregates. Their ability to handle significant amounts of goods makes them a great help for big-scale projects.

Lifelongity and Durability

Trommel screens mostly offer one advantage: durability. Strong construction and premium materials enable the Trommel screens to resist the most extreme working conditions. Whether they are running on heavy-duty materials like sand, gravel, or demolition waste, these machines are meant to last. For businesses, this longevity not only lessens the frequency of replacements but also over time lowers maintenance expenses, therefore saving money. Additionally, built to withstand abrasion and wear and tear are trommel screens. Usually built from high-strength steel or another wear-resistant material, the revolving drum guarantees its operation in even the most demanding surroundings.

Industry-Universal Adaptability

Trommel screens find applications in many different sectors and are flexible. In the building and mining sectors, they help to sort and separate materials including sand, gravel, and pebbles so improving the aggregate processing efficiency. In the recycling industry, trommel screens help to separate organic materials, plastics, and metals from trash therefore streamlining the recycling process and lowering landfill waste.

Enhanced Productiveness

The efficiency of trommel screens directly determines increasing production. By automating the sorting and separation process, these devices lower the manual effort needed for material sorting thereby freeing employees to focus on more important tasks. Trommel Screen also enable the simultaneous processing of large amounts of material, therefore accelerating the process and reducing congestion.

For companies trying to maximize material processing, cut running costs, and boost output, trommel screens are essential. In many different sectors, their high-efficiency performance, adaptability, and durability make them indispensable tools. Significant enhancements in productivity, operational efficiency, and long-term cost reductions can be achieved by investing in a high-quality trommel screen.